3-Axis Laser Weld Machine-Nooca otomaatig ah

Hordhac Product

Alxanka leysarka waxa uu isticmaalaa garaaca leysarka tamarta sare leh si uu deegaanka ugu kululeeyo shay meel yar.Tamarta shucaaca layserku wuxuu ku faafaa walaxda iyada oo la raacayo kulaylka, walxahana waa la dhalaalin si ay u sameeyaan barkad dhalaalaysa oo gaar ah.Waa nooc cusub oo alxanka ah, oo u badan alxanka walxaha gidaarka khafiifka ah iyo qaybo sax ah.Waxay xaqiijin kartaa alxanka barafka, alxanka dabada, alxanka tolmada, alxanka xidhidhiyaha, iwm.Qallafsanaan yar, xawaaraha alxanka degdega ah, tolmo alxanka siman oo qurux badan, looma baahna ama farsamayn fudud alxanka ka dib, tayada alxanka sare, dalool hawo lahayn, kontoroolka saxda ah, bar diirada yar, saxnaanta meelaynta sare, iyo fududahay in la ogaado automation.

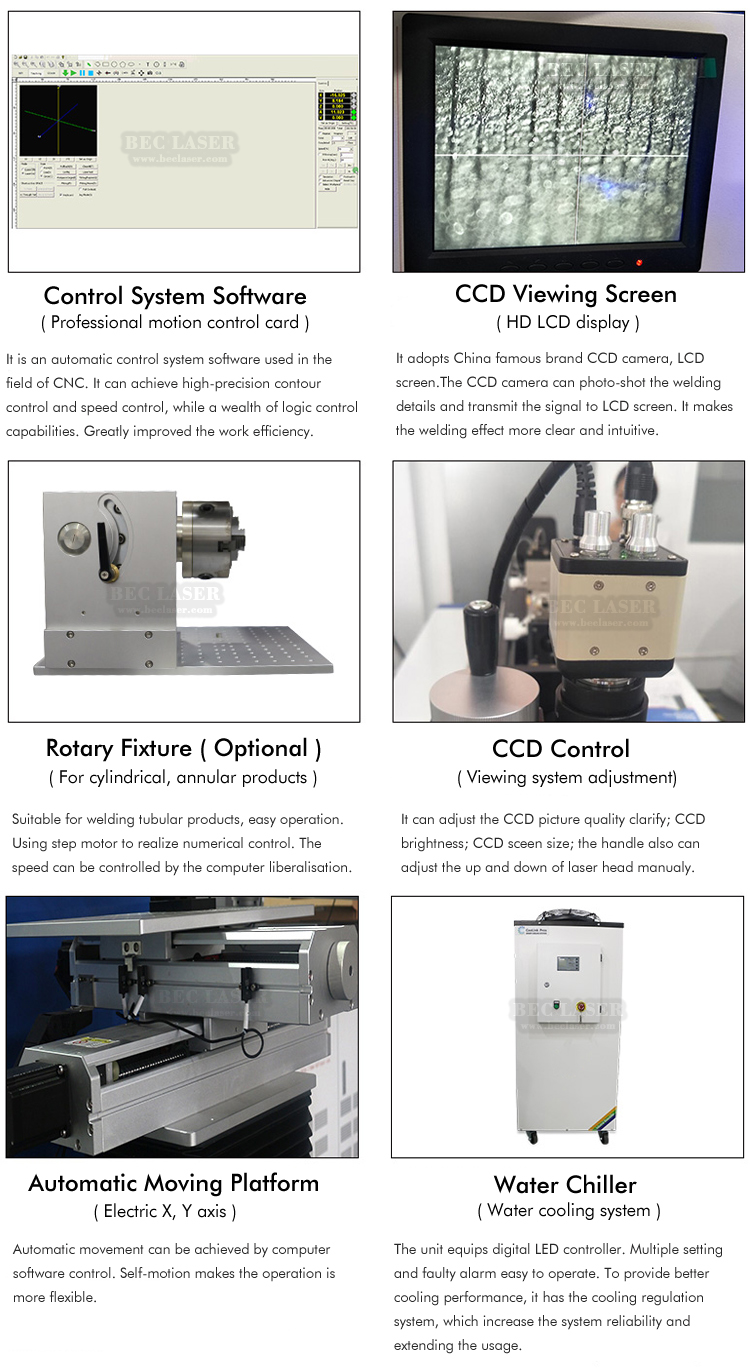

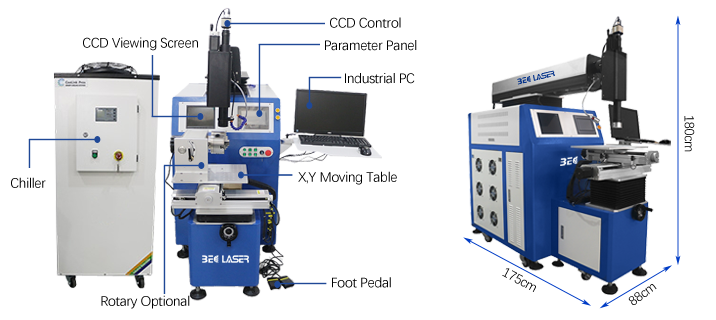

Dhammaantood waxay isticmaaleen naqshad saddex faas ah (afar faas ayaa la heli karaa), miiska shaqada ee X,Y si toos ah ayaa loo hagaajin karaa.Dhererka kursiga shaqada iyo dariiqa laysarka sidoo kale waa la hagaajin karaa.Software-ku wuxuu fuliyaa dhaqdhaqaaqa alxanka, meesha alxanka, xariiq toosan, goobada, oval iyo square iwm. raad diyaarad kasta iyo raad joomatari meel fudud.Ka sokow, mashiinkan waxaa loo isticmaali karaa in lagu hagaajiyo caaryada waaweyn oo miisaankeedu yahay tan, iyadoo la kaashanayo jirridda gariir-caddaynta iyo is-dheellitirka cagaha, way fududahay in laga saaro alaabtan.

Astaamaha

1. Isha laysarka waxay isticmaashaa tignoolajiyada horumarsan ee Jarmal, dalool dahab leh.Waxay leedahay dabeecadda tamarta sare ee wax soo saarka, waxqabadka xasilloon iyo dayactirka fudud.

2. Waxa ay leedahay software nidaamka gacanta si toos ah kaas oo gaari kara kontoroolka kontoroolka saxda ah sare iyo xawaaraha, halka hanti badan oo awood xakamaynta macquulka ah.Waxay si weyn u wanaajisay hufnaanta shaqada.

3. Awoodda laysarka waxaa lagu kiciyaa di-pulse XE-lamp, oo ay maamusho garaaca wadnaha joogtada ah, oo lagu qorsheeyay barnaamijka sirdoonka.

4. Taabo muraayadda shaashadda si aad u hagaajiso xuduudaha, taas oo ah mid fudud oo habboon.

5. Kursiga shaqada waa la qaadi karaa, waxaana loo dhaqaajin karaa saddex cabbir si toos ah.Madaxa laysarka iyo kursiga shaqada ayaa sidoo kale kor iyo hoos loogu qaadi karaa gacanta.

6. Kormeeraha CCD ha u ogolaado hawlwadeenku inuu si cad u eego raadraaca shaqada.

7. Qalab wareeg ah oo ikhtiyaar u ah hagaajinta walxaha anular cylindrical.

Codsiga

Waxaa lagu dabaqi karaa alxanka alxanka, koobabka faakuumka, maddiibaadaha birta ah, dareemayaasha, tungsten, Filamentiga, diodhka awoodda sare leh (triodes), aluminium alloys, xidhmooyinka laptops, baytariyada gacanta mobaylada, gacanta albaabka, dhinta, qalabka korantada, filtarrada, saliid nozzles. , Alaabooyinka birta ah, madax-kooxeedka golf-ka, farshaxanimada zinc alloy, iyo wixii la mid ah.

Halbeegyada

| Qaabka | BEC-AW200 | BEC-AW300 | BEC-AW400 | BEC-AW500 |

| Awoodda leysarka | 200W | 300W | 400W | 500W |

| Dhererka Mawjadaha Laser | 1064 nm | |||

| Max.Hal garaaca Tamarta | 80J | 100J | 120J | 150J |

| Nooca Laser | ND:YAG | |||

| Inta jeer ee garaaca Laser | 0.1-100Hz | |||

| Ballaca garaaca | 0.1-20ms | |||

| Kursiga shaqada | X=350mm, Y=200mm, oo qaadaya ilaa 200KG | |||

| X, Y, Dhaqdhaqaaqa Z | X, Y dhidibka si toos ah u dhaqaaqa;kala duwan 300 × 300mm (Ikhtiyaar ah), Z-dhidibka waa la qaadi karaa. | |||

| Nidaamyada Kormeerka | Microscope iyo nidaamka la socodka sawirka CCD si uu u weynaado | |||

| Nidaamka Xakamaynta | PLC ama PC & Microcomputer kantaroolka barnaamijka | |||

| Isticmaalka Korontada | 6KW | 10KW | 12KW | 16KW |

| Nidaamka qaboojinta | Biyo qaboojinta | |||

| Shuruudaha Awoodda | 220V± 10%/380V±10% 50Hz ama 60Hz | |||

| Baaxadda Baaxadda & Miisaanka | Mashiinka: 90 * 175 * 182cm, qaboojiyaha biyaha: 87 * 80 * 182cm;Miisaanka guud qiyaastii 660KG | |||

Tusaalooyinka

Qaab dhismeedka

Faahfaahin